We have over 25 years of experience welding & Fabrication experience

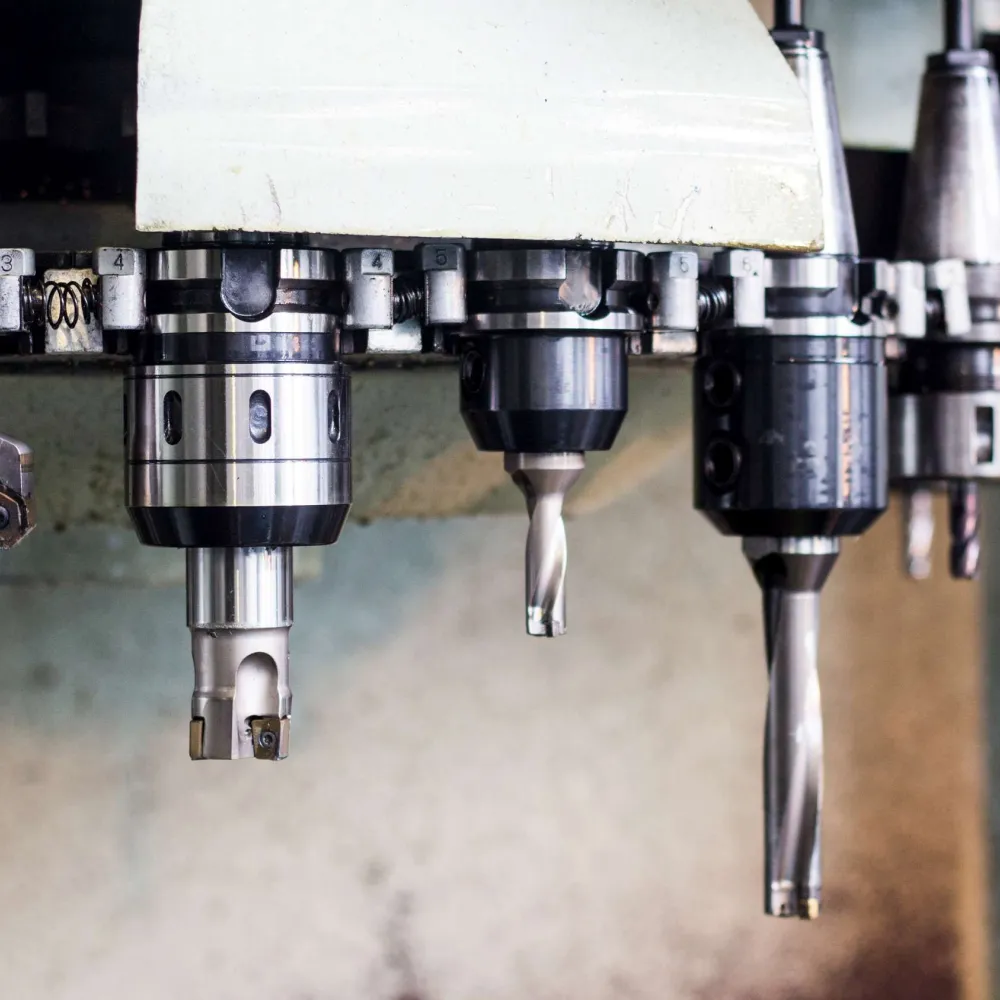

Our Fabrication Equipment:

Laser cutting, Mitsubishi, CO2 2700W, 5’x10’ bed size

Waterjet Flow Mach2 ,bed Size 72’’x120’’

CNC press brake, JFY, 150 TON x 3M

Services by third Party partners:

Coatings

- Zinc Phosphate

- Galvanized

- Plating

- Powder Coat

- Zinc

Heat Treatment

All treatments done in controlled atmosphere settings.

- Quench and Temper

- Carburizing

- Carbo-Nitriding

- Annealing

- Stress Relieve

- Nitriding

- Nitro-carburizing

- Ageing

- Precipitation Hardening

- Hot Isostatic Pressing

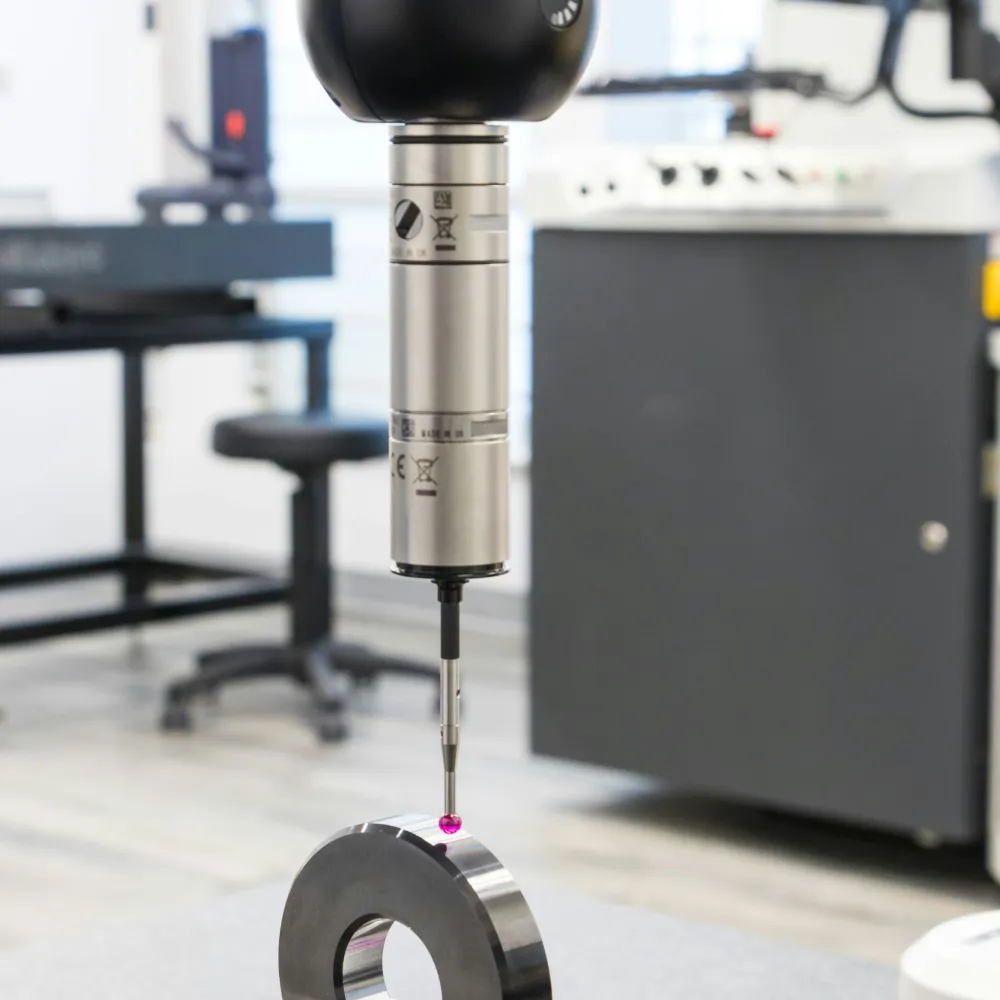

Lab Services include:

- Metallographic Analysis

- Hardness (All Rockwell scales)

- Superficial Hardness testing (15N, 30N, etc)

- Micro-Hardness (Vickers)

- % of Retained Austenite

- Micro-structure analysis

- Grain Size analysis

- Weld evaluation

Oil and Gas

What we have machined in the past for our valued customers:

- Parts for 1X Packers sizes - 4.50’’, 5.50’’, 7.00’’ and 8.625’’

- Parts for Hydro-Grip Packers - 4.50’’, 5.50’’ and 7.00’’

- Parts for X-6 Packers – 4.50’’ and 7.00’’

- Parts for R-3 Double Grip Packers – 5.50’’ and 7.00’’

- Parts for Torque Anchors

- Parts for WR Bridge Plugs – 5.50’’ and 7.00’’

- Parts for T-2 Overshoots

- Parts for Fishing necks

- Parts for Sliding Sleeves in various sizes.

- Parts for Many different parts for Flow Control.

- Parts for Setting Sleeves

- Parts for AD Tension Packers

Flanges:

CNC machined flanges are precision-engineered components used to connect pipes and other equipment in the oil and gas, chemical, and other industries. They are typically made from high-strength materials such as stainless steel, carbon steel, and titanium.

Connectors:

They can be made from a range of materials, including aluminum, stainless steel, brass, and plastics. CNC machining allows for precise tolerances and complex geometries, ensuring that connectors are manufactured to exact specifications.